Flow Test Bench for

About Flow Test Bench for

Reserach & Development

Field of application

- R&D Center, Tech Center, Universities

- Port development on cylinder heads (intake and exhaust)

- Optimization of air path component such as manifolds, air filters, particle filter

- Validation of Simulation

Challenge

- Evaluate quantity and quality of air flow at test parts

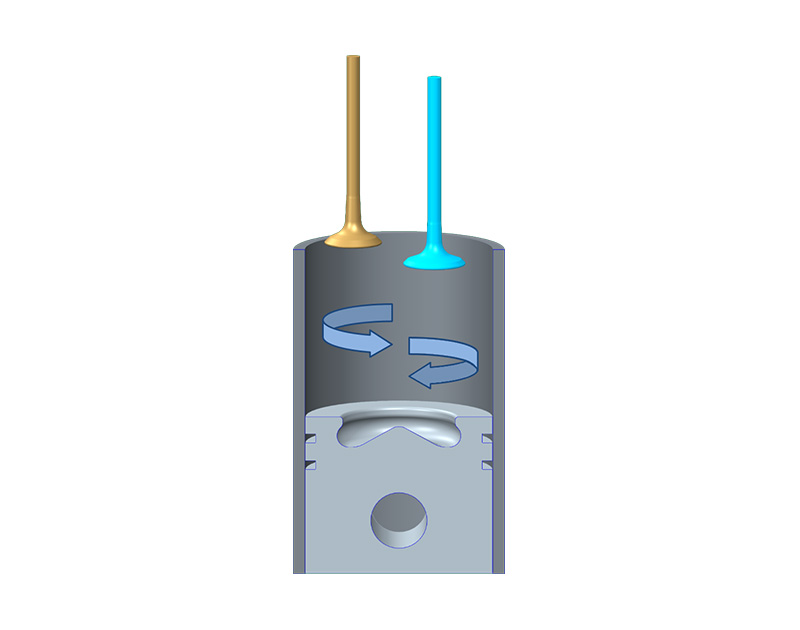

- Measure Tumble inside the cylinder liner

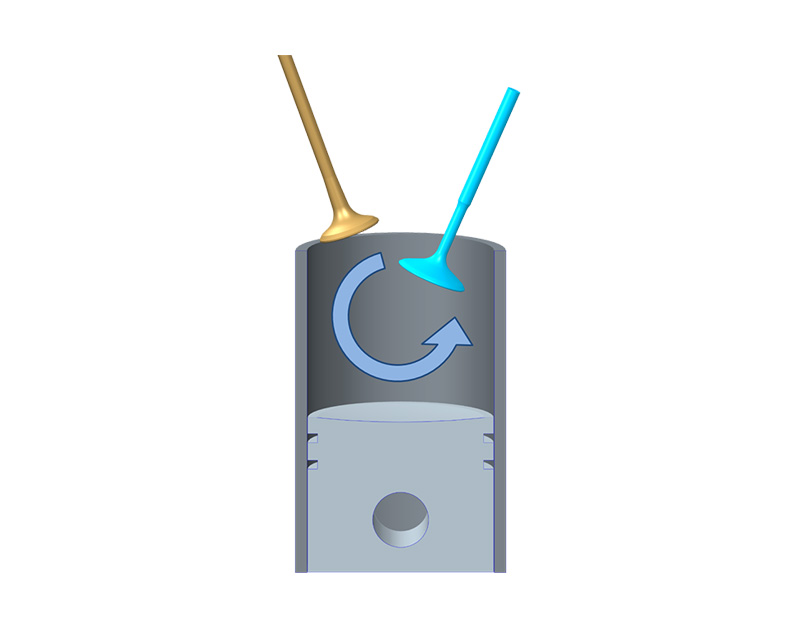

- Measure Swirl inside the cylinder liner

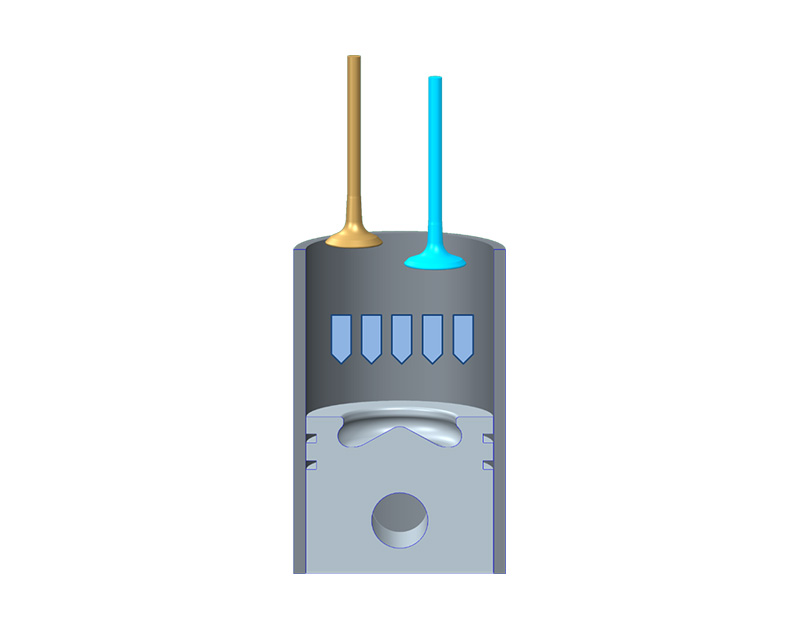

- Measure flow coefficients inside the cylinder liner or at peripheral components

SWIRL

FLOW COEFFICIENTS

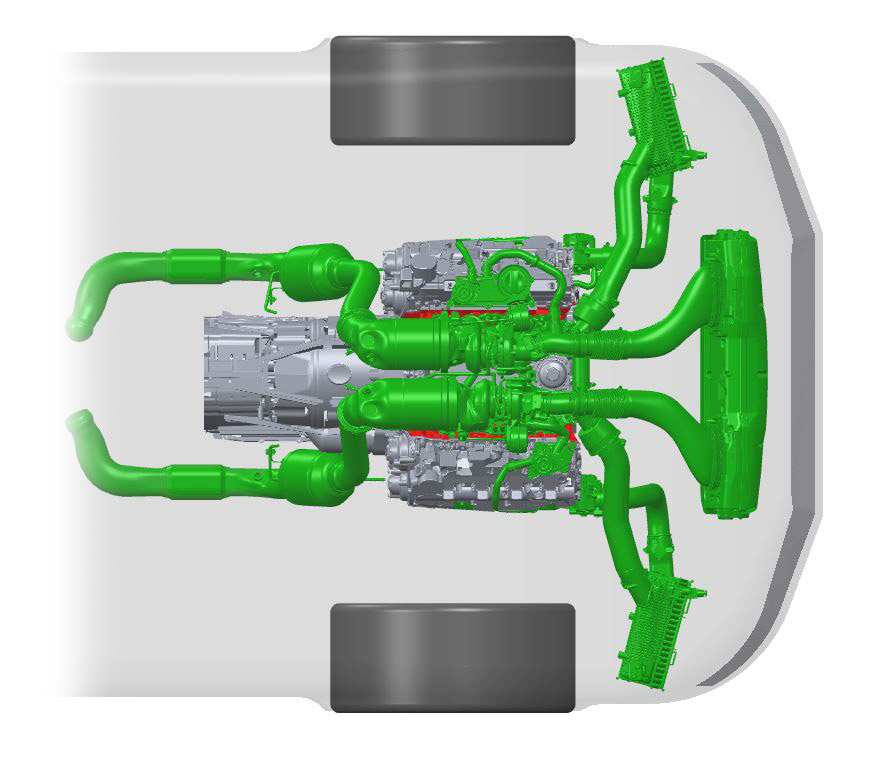

Exhaust system Testing

Multi Cylinder Head Testing

Catalyst and Particular Filter Testing

Air Filter and Air Box Testing

Intercooler Testing

Flow Test Bench for

PIV1000

PIV Flow Test Benches (Laser Optic)

In PIV-measurements (particle image velocimetry) microscopic particles are illuminated by laser light sheet during two closely timed pulses and simultaneously recorded photographically. Using two cameras the spatial components of particle motion are obtained, from which the three-dimensional velocity field in the measuring plane is determined. The velocity fields can be visualized and are well suitable for the validation of computational fluid dynamics results.

Similarly, the conventional flow characteristics (mass flow, Tippelmann swirl and tumble numbers) can be obtained from the velocity fields, allowing a quick comparison with results of the integral momentum measuring technique. In addition, other characteristics of the flow field, such as the position and orientation of the swirl and tumble axes or the omega tumble value can be determined, further contributing to the evaluation and documentation of the influences of air-conducting components.

Field of application

- Cars, motorcycles, light duty engines, motorsport

- High end intake port development

- Flow field analysis

- Investigation of dynamic effects

- Direct CFD validation

Added value

- Detailed three-dimensional flow field information

- Fully integrated PIV system (auto-controlled)

- Integrated calculation of relevant flow characteristics (no manual post processing)

- Fully automated measuring process for maximum performance, quality and safety

- Simplified operation, no engineer required

- Convenient for scan of complete cylinder volume

- Comparability to integral momentum measuring method (Tippelmann Swirl and Tumble)

- Safety requirements for industrial use are met

| Type | PIV1000 |

|---|---|

| Measurement | Particle Image Velocimetry |

| Measured values / output / flow investigation on | Tumble Swirl Flow coefficients 3D vector field |

| Bore range | Up to 100 mm |

| Max. differential pressure | 100 hPa |

| Max. mass flow | 1000 kg/h |

| Max. cylinder head weight | 50 kg |

Flow Test Bench for

PIV2000

PIV Flow Test Benches (Laser Optic)

In PIV-measurements (particle image velocimetry) microscopic particles are illuminated by laser light sheet during two closely timed pulses and simultaneously recorded photographically. Using two cameras the spatial components of particle motion are obtained, from which the three-dimensional velocity field in the measuring plane is determined. The velocity fields can be visualized and are well suitable for the validation of computational fluid dynamics results.

Similarly, the conventional flow characteristics (mass flow, Tippelmann swirl and tumble numbers) can be obtained from the velocity fields, allowing a quick comparison with results of the integral momentum measuring technique. In addition, other characteristics of the flow field, such as the position and orientation of the swirl and tumble axes or the omega tumble value can be determined, further contributing to the evaluation and documentation of the influences of air-conducting components.

Field of application

- Commercial engine medium to heavy duty

- High end intake port development

- Flow field analysis

- Investigation of dynamic effects

- Direct CFD validation

Added value

- Detailed three-dimensional flow field information

- Fully integrated PIV system (auto-controlled)

- Integrated calculation of relevant flow characteristics (no manual post processing)

- Fully automated measuring process for maximum performance, quality and safety

- Simplified operation, no engineer required

- Convenient for scan of complete cylinder volume

- Comparability to integral momentum measuring method (Tippelmann Swirl and Tumble)

- Safety requirements for industrial use are met

| Type | PIV2000 |

|---|---|

| Measurement | Particle Image Velocimetry |

| Measured values / output / flow investigation on | Tumble Swirl Flow coefficients 3D vector field |

| Bore range | Up to 200 mm |

| Max. differential pressure | 100 hPa |

| Max. mass flow | 1850 kg/h |

| Max. cylinder head weight | 350 kg |

Flow Test Bench for

FTB450

Flow Test Benches (Momentum)

Modern combustion engines must meet continuously increasing demands for efficiency and exhaust gas quality. All air-conducting components, in particular the intake and exhaust ports in the cylinder head, determine the in-cylinder flow and thus have a decisive influence on the combustion characteristic. When evaluating these influences an accurate, reproducible measurement of qualitative and quantitative flow characteristics is essential.

The method to determine Tippelmann swirl and tumble numbers is based on the integral detection of the momentum components embedded in the flow. It has been developed and patented by AVL Tippelmann and is now established at all major engine manufacturers.

AVL Tippelmann flow test benches are suitable for a wide range from motorcycle, car and truck up to big engines.

Field of application

- Cars, motorcycles and light duty engines

- Intake and exhaust port development

- Integral analysis of flow field for Tumble, Swirl and capacity

- Quality check

- CFD validation

Added value

- One- and three-dimensional flow field information

- Fully automated measuring process for maximum performance, quality and safety

- Simplified operation, no engineer required

- Comparability to PIV measuring method

- Fast measurement process

- Noise cancelation enclosure available

- Precise and fast measurement

| Type | FTB450 |

|---|---|

| Measurement | Momentum detection by flow straightening |

| Measured values / output / flow investigation on | Tumble Swirl Flow coefficients |

| Bore range | Up to 116 mm |

| Max. differential pressure | 70 hPa |

| Max. mass flow | 450 kg/h |

| Max. cylinder head weight | 50 kg |

Flow Test Bench for

FTB2000

Flow Test Benches (Momentum)

Modern combustion engines must meet continuously increasing demands for efficiency and exhaust gas quality. All air-conducting components, in particular the intake and exhaust ports in the cylinder head, determine the in-cylinder flow and thus have a decisive influence on the combustion characteristic. When evaluating these influences an accurate, reproducible measurement of qualitative and quantitative flow characteristics is essential.

The method to determine Tippelmann swirl and tumble numbers is based on the integral detection of the momentum components embedded in the flow. It has been developed and patented by AVL Tippelmann and is now established at all major engine manufacturers.

AVL Tippelmann flow test benches are suitable for a wide range from motorcycle, car and truck up to big engines.

Field of application

- Cars, motorcycles and light duty engines, motorsport

- Intake and exhaust port development

- Optimization of peripheral components (manifold, air filter, mass flow meter, particle filter)

- Integral analysis of flow field for Tumble, Swirl and capacity

- Quality check

- CFD validation

Added value

- One- and three-dimensional flow field information

- Fully automated measuring process for maximum performance, quality and safety

- Simplified operation, no engineer required

- Comparability to PIV measuring method

- Fast measurement process

- Noise cancelation enclosure available

- Precise and fast measurement

| Type | FTB2000 |

|---|---|

| Measurement | Momentum detection by flow straightening |

| Measured values / output / flow investigation on | Tumble Swirl Flow coefficients |

| Bore range | Up to 116 mm |

| Max. differential pressure | 100 hPa |

| Max. mass flow | 1000 kg/h |

| Max. cylinder head weight | 50 kg |

Flow Test Bench for

FTB2000 boosted

Flow Test Benches (Momentum)

Modern combustion engines must meet continuously increasing demands for efficiency and exhaust gas quality. All air-conducting components, in particular the intake and exhaust ports in the cylinder head, determine the in-cylinder flow and thus have a decisive influence on the combustion characteristic. When evaluating these influences an accurate, reproducible measurement of qualitative and quantitative flow characteristics is essential.

The method to determine Tippelmann swirl and tumble numbers is based on the integral detection of the momentum components embedded in the flow. It has been developed and patented by AVL Tippelmann and is now established at all major engine manufacturers.

AVL Tippelmann flow test benches are suitable for a wide range from motorcycle, car and truck up to big engines.

Field of application

- Flow measurement at high differential pressure up to 400 hPa

- Cars, motorcycles and light duty engines, motorsport

- Intake and exhaust port development

- Optimization of peripheral components (manifold, air filter, mass flow meter, particle filter)

- Integral analysis of flow field for Tumble, Swirl and capacity

- CFD validation

Added value

- One- and three-dimensional flow field information

- Fully automated measuring process for maximum performance, quality and safety

- Simplified operation, no engineer required

- Comparability to PIV measuring method

- Fast measurement process

- Noise cancelation enclosure available

- Precise and fast measurement

| Type | FTB2000 boosted |

|---|---|

| Measurement | Momentum detection by flow straightening |

| Measured values / output / flow investigation on | Tumble Swirl Flow coefficients |

| Bore range | Up to 116 mm |

| Max. differential pressure | 400 hPa |

| Max. mass flow | 1000 kg/h |

| Max. cylinder head weight | 50 kg |

Flow Test Bench for

FTB2000CE

Flow Test Benches (Momentum)

Modern combustion engines must meet continuously increasing demands for efficiency and exhaust gas quality. All air-conducting components, in particular the intake and exhaust ports in the cylinder head, determine the in-cylinder flow and thus have a decisive influence on the combustion characteristic. When evaluating these influences an accurate, reproducible measurement of qualitative and quantitative flow characteristics is essential.

The method to determine Tippelmann swirl and tumble numbers is based on the integral detection of the momentum components embedded in the flow. It has been developed and patented by AVL Tippelmann and is now established at all major engine manufacturers.

AVL Tippelmann flow test benches are suitable for a wide range from motorcycle, car and truck up to big engines.

Field of application

- Commercial engine, medium to heavy duty

- Intake and exhaust port development

- Optimization of peripheral components (manifold, air filter, mass flow meter, particle filter)

- Integral analysis of flow field for Tumble, Swirl and capacity

- Quality check

Added value

- One- and three-dimensional flow field information

- Fully automated measuring process for maximum performance, quality and safety

- Simplified operation, no engineer required

- Comparability to PIV measuring method

- Fast measurement process

- Precise and fast measurement

| Type | FTB2000CE |

|---|---|

| Measurement | Momentum detection by flow straightening |

| Measured values / output / flow investigation on | Swirl Flow coefficients Tumble |

| Bore range | Up to 180 mm |

| Max. differential pressure | 100 hPa |

| Max. mass flow | 1850 kg/h |

| Max. cylinder head weight | 350 kg |