Acoustic Cavity Check System

ACCS

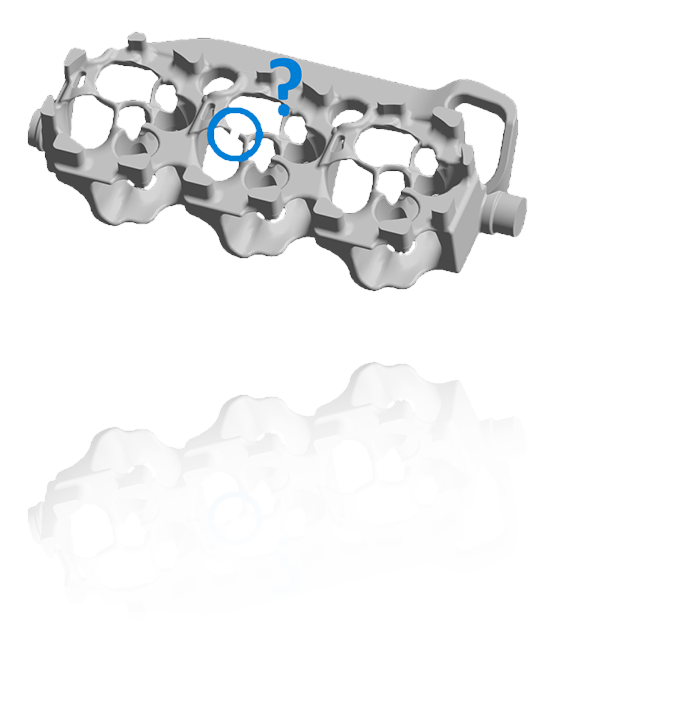

Complex shaped cavities can be examined efficiently using the acoustic cavity inspection system ACCS developed and patented by AVL Tippelmann. For this purpose, a sound signal is introduced at an opening of the cavity. The transmitted signal is recorded at one or more other openings. The transmission behavior is essentially determined by the geometry of the cavity. Deviations in phase and frequency response compared to correctly shaped cavities are thus due to geometric errors in the examined cavity. Therefore the method is suitable to detect inclusions and full or partial blockages in castings.

A typical application is the testing of water jackets in cylinder heads in series production featuring a complex branched and meshed structure.

Field of application

- Suitable for complex shaped cavities (e.g. water jackets)

- High volume cast production

- Rejection of critical parts after first cut

ACCS SA

Semi-automated

Cycle Time: 3,5 min

ACCS FA

Fully-automated

Cycle Time: 2,5 min

Added Value

- Short cycle times enable 100 % QC in serial production

- Automated measurement sequence and part evaluation

- Robust measurement instrumentation

- Low wear and low maintenance

- Low energy consumption